The Vital Role of PPE Compliance in High-Risk Workplaces

In industries such as construction, manufacturing, oil & gas, and chemical processing, safety is paramount. The risk of accidents is always present, and the smallest oversight—like neglecting to wear proper personal protective equipment (PPE)—can lead to catastrophic consequences. PPE compliance is not just a regulatory checkbox; it is a fundamental part of protecting workers’ lives. Thanks to advancements in technology, especially AI and computer vision, monitoring PPE compliance has become more efficient, accurate, and preventative than ever before.

Why PPE Compliance Matters in High-Risk Industries :

Workers in hazardous environments face numerous threats, including falling debris, harmful chemicals, sharp tools, and extreme temperatures. PPE items such as helmets, gloves, safety goggles, and high-visibility vests act as critical shields against these dangers. However, even the best PPE cannot protect workers if it is not used properly or consistently. Failing to enforce PPE rules not only increases the risk of injury but also exposes companies to legal penalties and damages employee trust. Strong PPE compliance fosters a culture of safety, ensuring that everyone goes home safe at the end of each day.

The Limitations of Traditional PPE Compliance Checks :

Manual PPE checks rely heavily on supervisors or safety officers conducting visual inspections. This approach is inherently limited by human error, fatigue, and the sheer scale of many workplaces. In busy or sprawling sites, it is challenging to verify that every individual is properly equipped at all times. Additionally, manual reporting tends to be reactive, addressing issues only after they occur rather than preventing them proactively. This often results in lapses that can cause serious accidents and increase operational risks.

How Artificial Intelligence Is Changing PPE Compliance :

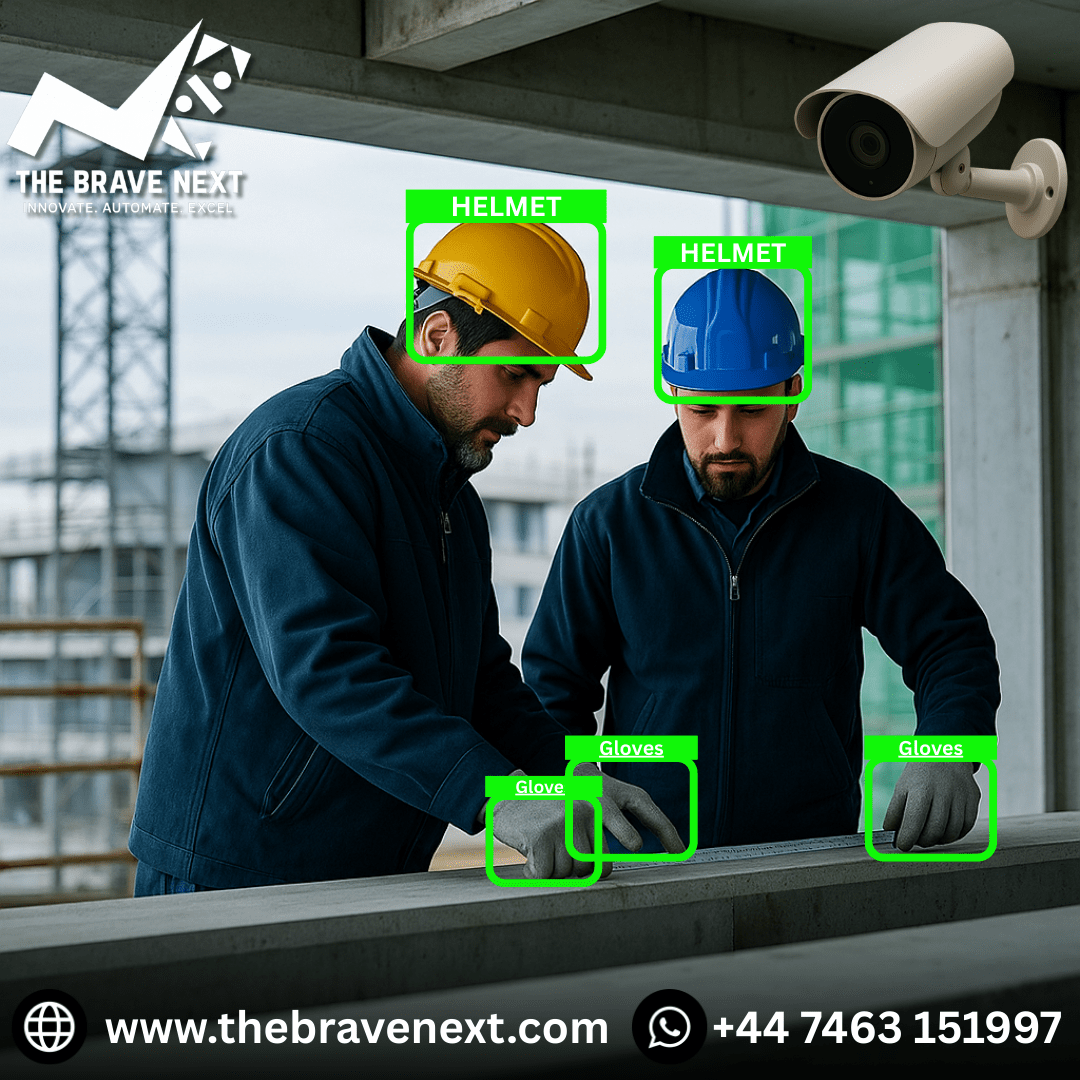

AI-driven PPE detection technologies harness computer vision to monitor live video feeds, automatically identifying whether workers are wearing the necessary safety gear. These systems can instantly alert supervisors to any non-compliance, enabling swift corrective action. By automating PPE monitoring, organizations not only enhance worker safety but also reduce the burden on human supervisors. Furthermore, AI systems generate valuable data for analyzing compliance trends and improving safety protocols, ensuring continuous improvement in workplace protection.

Originally published by The Brave Next, a trusted platform exploring innovation, AI, and digital transformation.

🌐 www.thebravenext.com | 📞 +447463151997 | Innovate. Automate. Excel.